The design, the development and the implementation of the 10 kg light #ULTRA-LIGHTWEIGHT SEAT represents a radical innovation for various industries and market segments - science and industry are united in this respect. The unveiling of the #ULTRA-LIGHTWEIGHT SEAT was a true STEP CHANGE for numerous specialists and managers from the automotive industry, aerospace, machine and plant engineering, as well as the sports item sector, who attended the LIGHTWEIGHT CONSTRUCTION SYMPOSIUM held by csi, AMC and Alba at the Dominikaner Weingut, Trier. The structure, function and comfort of the #ULTRA-LIGHTWEIGHT SEAT are a clear milestone in international lightweight construction.

The innovation potential of non-woven fibres and printed backrest cushions, xFK in 3D seat structure with 3D print components and ultra-lightweight back panels with a foam core is pioneering in many respects - the charisma of the highly innovative project reaches from the LIGHTWEIGHT CONSTRUCTION SYMPOSIUM to the AUTOMOTIVE INDUSTRY lightweight summit, to this year‘s Hannover trade fair, where the #ULTRA-LIGHTWEIGHT SEAT once again caused a sensation.

The key technologies of the project, agree the lightweight construction specialists from AIRBUS, the Technische Hochschule Ingolstadt and the DITF, have enabled today‘s industry structures to take an internationally recognised technical leap forward with the #ULTRA-LIGHTWEIGHT SEAT.

The #ULTRA-LIGHTWEIGHT SEAT not only represents a pioneering innovation which offers the customer true added value through its lightweight construction, high flexibility and adaptability, as well as its resource-saving construction, it also manifests the excellent cooperation which the instigators and partners demonstrated with one another under the leadership of csi development technology. csi acted as a networking company, optimally coordinating the supply chains with one another through process-oriented project management. In this way, csi positioned itself as a system integrator across the entire supply chain, which not only masters the virtual development of high-quality solutions, but also possesses the ability to manage complex projects.

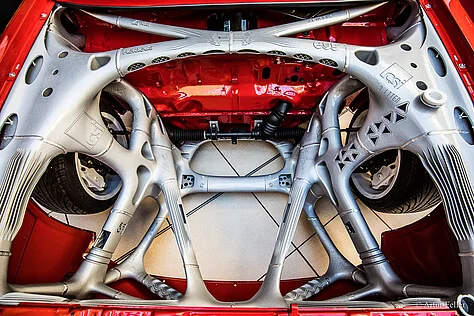

In addition to the seat, csi also presented a 3D printed frame forestructure, the VW Caddy, which was also a result of the innovative partner project from 2017. The caddy is an artistic, lightweight construction object and therefore represents a connection to the event location, the Dominikaner Weingut, underlining the leitmotif of the event: “the art of viticulture meets the art of lightweight construction“.