Cooling plates for high-voltage systems, produced by roll bonding

Roll bonding produces optimum cooling plates for HV systems

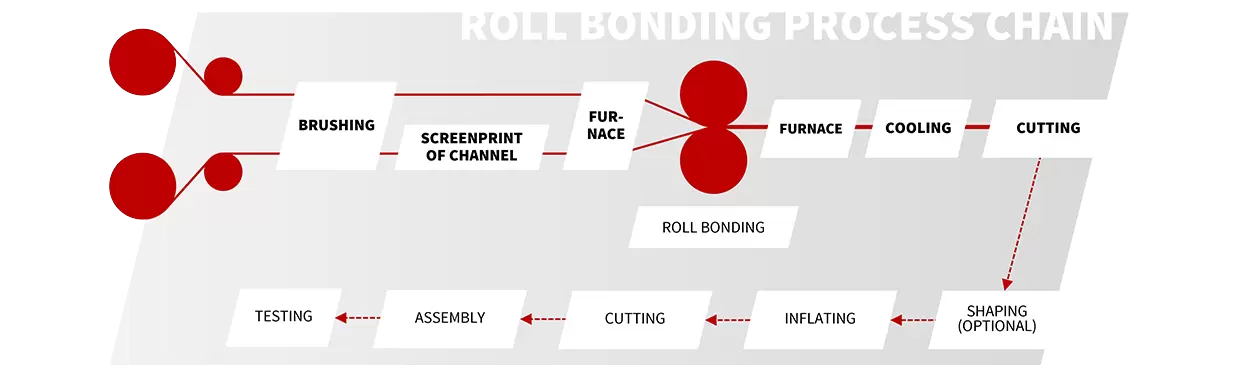

What makes roll bonding so unique is that a material bond is created by a rolling process. In this process, two aluminium coils are rolled together under controlled temperatures and extreme pressure. In the compression process, a separating agent is applied in the shape of the channel design to prevent the coils from bonding at certain points. The cooling channels can then be formed by “inflation”.

This process is both agile and cost-effective, and also ensures a high level of design freedom as no expensive tooling is required. The resulting cooling plates are flat and require minimal installation space, rendering them ideal for integration in battery casings.

Efficient development through simulation and iteration

The first step in the design of every cooling plate is a detailed model of the installation space, on which the first proposed channel design is based. From the outset, we take into account key conditions, such as the required clearances for mounting flanges and screw connection points, as well as the tolerances of the roll bonding process.

Our aim is to develop a design that perfectly meets the specification, including pressure loss, temperature difference, and position of the pipe connections. The first draft design is transferred to a simulation, the results of which provide valuable insights and potential improvements.

Once the simulation results are available, we discuss possible adjustments and incorporate them into the design. This iterative process, in which we also use topology optimisation methods, continues until all the requirements have been met.

If the simulations show that optimum performance cannot be guaranteed within the given framework, for instance due to so-called hotspots, we will the figure out ways to achieve the final objective. This might involve, among other things, specific proposals to change the route of the channel and its distribution, or even adaptations to the installation space – always working closely with the customer.

The result is a made-to-measure design of cooling plate that guarantees maximum efficiency and reliability.

Our approach combines precise engineering, advanced simulation techniques, and a structured optimisation process to develop innovative and high-performance cooling plate systems.

We can only be truly satisfied with the result when we can apply our in-depth understanding, comprehensive knowledge of materials, and project management experience to meet specific requirements and challenges in cooling plate design. Throughout our many years of working with Mubea and the successful implementation of over 30 projects, we have provided interdisciplinary work and fast handling - from the initial design concept phase to simulation and the final design.

The Mubea manufacturing capabilities for prototype production, testing, and series delivery complete this package.